Photos: from top: David Schneider; Altaeros Energies; Makani Power

Tower-mounted wind turbines dot the landscape, but airborne systems offer some surprising advantages

LIGHT AIRS: The author holds one of the off-the-shelf kiteboarding kites used to test the WindLift generator, waiting for the wind to pick up enough for a good launch [top]. Altaeros Energies lofts a lighter-than-air turbine [middle]. Makani Power mounts motor-generators on a rigid wing [bottom.] Click to enlarge.

Raising money to fund product development is never easy, as any tech entrepreneur will tell you. But I’ve had to grapple with a unique complication: My company, WindLift, is developing a kite-based system that generates electricity. The prototype, designed to put out 12 kilowatts, could save tons of money for some people now using diesel generators. But when I pitch the business to potential investors, it often seems as if all they can remember is their childhood struggles with those cheap stick-and-string fliers, making it impossible for them to envisage what my company aims to achieve.

The problem isn’t so much that most people view kites as toys—it’s that most people have no idea how sophisticated those toys have become! Take kiteboarding. Since the mid-1990s, a growing number of enthusiasts have been using large kites to enjoy an experience similar to that of waterskiing or skimming over the water on a wakeboard while being pulled by a motorboat. With kiteboarding, you dispense with the boat and are instead pulled across the waves by a good-size kite.

The kites designed for this sport measure up to 20 square meters, almost as big as a small billboard. With them, expert kiteboarders can really fly: In 2010, the world’s speed-record holder, Rob Douglas, hit 103 kilometers per hour (64 miles per hour)—faster than the fastest sailboat. And skilled kiteboarders can leap 15 or more meters into the air and then glide back gently to the water’s surface.

A kite capable of such feats isn’t anything like the ones you played with as a kid—it’s an ingeniously engineered airfoil. And by the way, it has high-tech tethers that are 15 times as strong as steel. A lot of research has gone into designing such kites and their rigging so that they can be turned on a dime with a gentle tug on the control lines. They can also be instantly adjusted to reduce the power they deliver, an important feature that allows a kiteboarder to negotiate strong, gusty winds safely.

Given these advances in kite engineering, it should come as little surprise that several companies are now trying to deploy this technology for something more than recreation. A few have attached large kites to cargo ships and motor yachts as a way to reduce their fuel consumption. My company is looking to use these airfoils to offset fuel use, too, but in a different setting—for electrical generators in remote locations where the diesel fuel to run them is a scarce commodity. Diesel in these places is so expensive that supplementing conventional generators with power produced from the wind makes good economic sense.

Mine is just one of several ongoing efforts to use kites to generate electrical power from the wind. Such airborne wind-energy systems offer many advantages over standard wind turbines, most notably that these tethered airfoils can tap the relatively strong and steady winds found higher up. In addition, the area the airfoil can sweep isn’t limited by the diameter of the turbine, so these airborne systems are inherently more efficient. Finally, the massive pylon needed to support a very large rotating blade can be eliminated, slashing construction costs and setup times.

Of course, generating electricity with a kite has some challenges you don’t have with a standard wind turbine. Turbines can’t crash, for example. To avoid such mishaps, you must be able to control the kite so that it crisscrosses the sky in an orderly fashion, despite the vagaries of the wind. You also need to automate this piloting and to make the whole system robust and reliable. So far, nothing that meets all those requirements has emerged on the commercial market, and it will probably be several years at least before anything is available that does.

I view the present situation as being akin to the pioneering days of flight, where nobody knew what configuration of wings and control surfaces would serve best—or whether the whole enterprise would prove practical at all. But if the engineers now working on this technology are persistent and clever enough, using tethered wings to generate electricity from the wind will surely progress just as quickly as early aviation did.

Photos: David Schneider (4)

FIELD TESTS: WindLift tests parts of its prototype system, including the airborne telemetry [top left], a leading-edge-inflatable kite [top right, bottom left], and a tether-wrapped drum [bottom right]. Click to enlarge.

As far back as the early 19th century,some kites were used as a power source—to propel buggies. But the first rigorous technical analysis of kites for generating electricity began in about 1980. Miles Loyd, a researcher at Lawrence Livermore National Laboratory, in California, investigated the physics of the problem, publishing his results in a journal article titled “Crosswind Kite Power” [PDF].

Loyd showed that by flying a tethered wing back and forth across the wind, you could get considerably more power than you could from a kite that just hovered in one spot. According to Loyd’s calculations, if you used a wing as big as the one on a Lockheed C-5A military transport (68 meters long), you could, at least in principle, extract a few megawatts from a 10-meter-per-second wind. That’s comparable to what you might get from the biggest of modern wind turbines.

Loyd considered two ways to get electrical energy out of a tethered wing. One is to outfit the wing itself with propeller-like turbine blades that generate power as it zooms through the air. That power would then be sent down an electrically conductive tether. This is now known as the flying-generator, or “flygen,” approach. The other technique he considered was to exploit the force that the wing exerts on its tether to generate electricity using equipment on the ground.

Loyd’s analysis didn’t examine yet another possibility: to generate electricity using turbine blades that serve as both lifting surfaces and energy-harvesting devices. That’s the technique Australian engineer Bryan Roberts began experimenting with in 1979—something he calls a gyromill, which he continues to work on with California-based Sky Windpower.

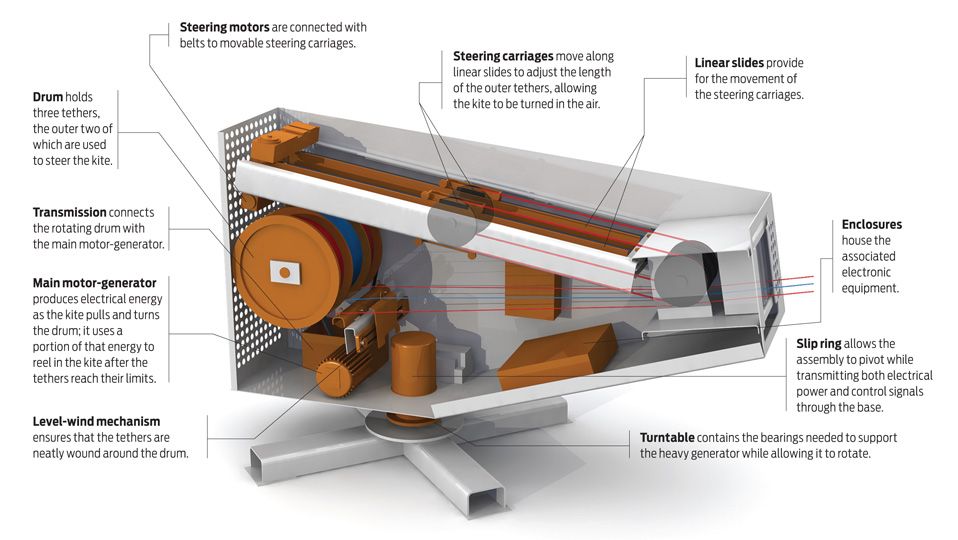

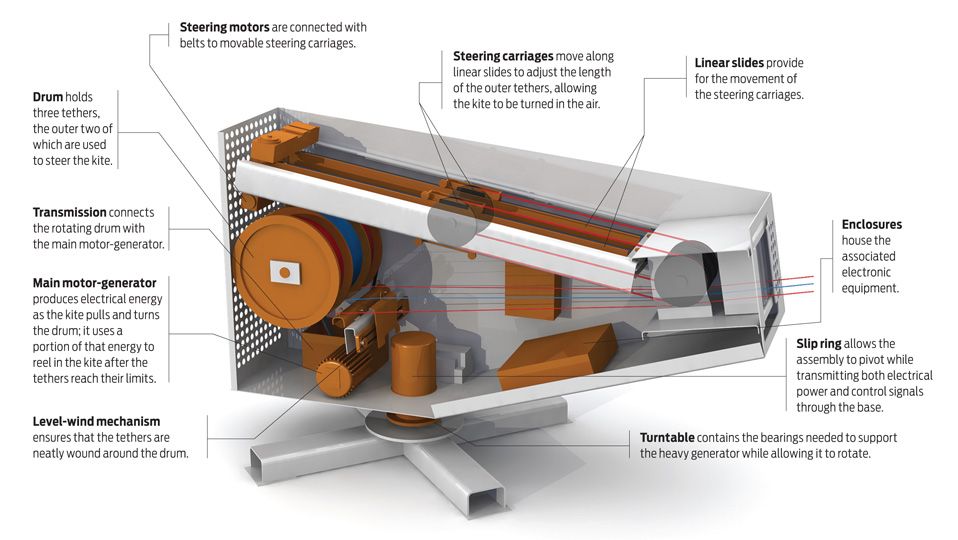

Illustration: John MacNeill

KITE-POWER MACHINE: A LOOK INTO THE INNER WORKINGS OF WINDLIFT’S PROTOTYPEThe author’s company, WindLift, built an airborne wind-energy system for engineering tests. It uses a leading-edge-inflatable kite and a ground-based generator, the main components of which are shown here. Click to enlarge.

Beginning in the 1990s, other groups around the world also began devising various ways to generate electricity with kites. But most of their plans involved ambitiously large systems that never materialized despite the many patents filed for them. Perhaps the most influential of these early innovators was Wubbo Ockels, the first Dutch astronaut, who proposed the multikite Laddermill in 1993. Although the Laddermill was never built, Ockels, now a professor of aerospace engineering, has created a well-regarded research and development program in airborne power generation at the Delft University of Technology, in the Netherlands.

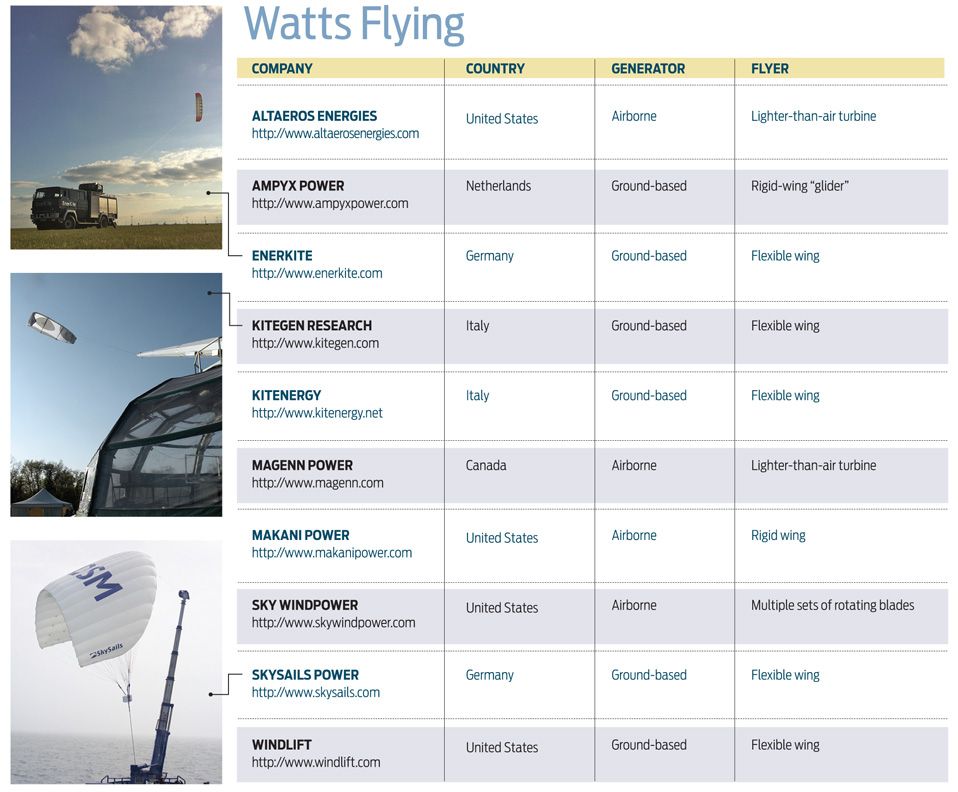

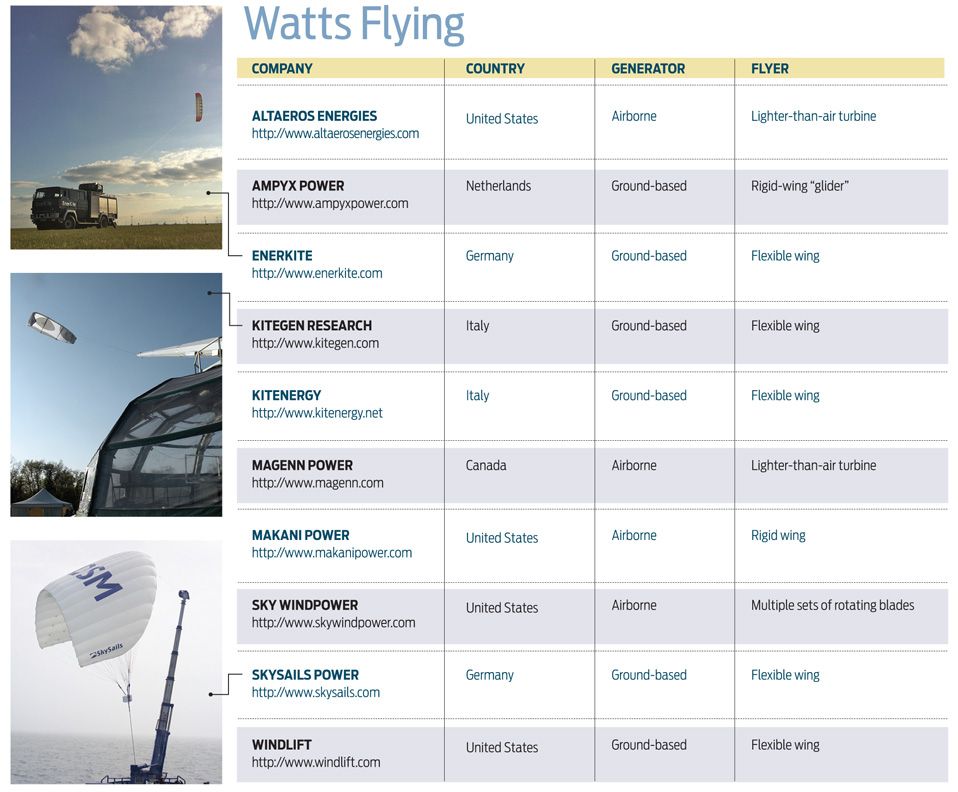

Stephan Wrage, one of the founders of Hamburg-based SkySails, is another leading figure in this field, having raised more than US $70 million to develop kites for ship propulsion. The list of people and companies working on airborne wind energy goes on, with many attractive ideas still incubating [see table, “Watts Flying”].

Photos: From top: Enerkite; Kitegen research; Skysails Power

I began thinking about using kites to generate electrical power in 2005. I had just returned from a trip to Honduras, where there is a dire need for affordable power in areas not connected to the grid. Many of the people I met in the country’s rural districts relied on diesel generators, but fuel costs limited how often they could run them.

This same problem continues to hold back much of the developing world. Even mobile telephony in such places often depends on running diesel generators constantly, inflating the cost of wireless service. Indeed, the London-based GSM Association estimates that mobile-phone providers spend about $15 billion a year worldwide on diesel fuel for remote base stations.

The scarcity of diesel is also a big issue in war zones, where delivering fuel to mobile generators can cost close to $4 for each kilowatt-hour of electricity generated—tens of times the price that grid-connected consumers typically pay. So if kite power could offset even a fraction of that fuel consumption, there would be considerable savings for the military, both in money and in lives lost protecting resupply lines.

I began exploring ways to use kites to supplement diesel-powered generators while I was a first-year MBA student at the University of Wisconsin–Madison. My initial concepts ran the gamut. Totally ignorant of the earlier efforts in this sphere, I had naive ideas about what would work. Nevertheless, I founded WindLift and began looking for funding for research and development.

My first meeting with a venture capitalist brought in no money, but I got some good advice: He said I should investigate kiteboarding—a sport he had discovered while vacationing in Hawaii. After a quick Internet search, a world of expertise in harnessing the energy of big kites opened up to me. And to be sure I learned all the lessons it had to offer, I took up the sport myself.

The people constructing kites for kiteboarding have roughly the same goals as those designing kite-energy machines—to create maximum tension in the lines, which is why WindLift has been able to use off-the-shelf kiteboarding kites to test its prototype systems, the first of which I built mostly myself. In 2008, I moved my fledgling company from Wisconsin to North Carolina to take advantage of the excellent coastal winds and longer testing season there—the same reasons the Wright brothers went to North Carolina’s Kitty Hawk in 1900. Alas, the state’s coasts have been highly developed since then, and the lonely dunes over which the Wrights flew are now trampled by millions of tourists each year. So WindLift’s engineers and I conduct test flights in open fields several kilometers inland.

Our current system uses a 90-centimeter-diameter drum, which is connected to a 60-kW motor-generator built originally for a hybrid electric bus. Tension from the kite pulls the tether and turns the drum, thus generating electricity, which is stored in a bank of lead-acid batteries. Control lines attached to the wing are then adjusted to “depower” the kite, reducing the amount of lift it produces. During this phase of the cycle, electricity is fed back into the motor-generator, rotating the drum in the other direction and reeling in the kite.

We constructed our initial prototypes using ram-air wings, which are similar to those found on modern parachutes. We soon realized, though, that some internal structure was needed to stabilize flight during the retract cycle. That’s when you want the lift provided by the wing to drop to zero—or even better, to become negative, meaning that the air pushes it downward.

Ram-air wings can’t be depowered much without them completely folding up. So we switched to a leading-edge inflatable (LEI) kite, which has a long, slender air bladder at the front of the wing to help it hold its form. Even so, these wings may prove too flexible to execute a reliable retract cycle. We’re working now to find ways to reinforce them without making them so stiff that they (or the things they hit) sustain damage on hard landings. If we’re not successful, the need to be able to reel in the kite without expending much energy may ultimately force us to adopt completely rigid wings.

So far, we’ve built two ground stations and have been testing them with LEI kites normally used for kiteboarding. Those wings cannot, however, generate the huge amount of tension we configured our system for. That will soon come from new wings of our own design, which we expect to begin flying next year. In the meantime, with only standard kiteboarding kites attached, our system cannot generate much power. But our experiments with them have allowed us to compare field measurements with our numerical models and also to work on telemetry electronics and automated flight controls.

We’re not the only ones getting ready to test the winds. Among our competitors, the most advanced are using rigid wings rather than ones made of fabric. These designs tend to be more expensive, and the wings are prone to damage when they strike the ground. But those rigid airfoils are far more aerodynamic than any fabric wing, allowing them to extract more power from the wind.

Makani Power of Alameda, Calif., is one of the leading companies taking this approach. With $15 million in seed money from Google and a $3 million grant from the U.S. Advanced Research Projects Agency’s ARPA-E program, along with other private investment, Makani has built large carbon-composite wings, each outfitted with four propeller-equipped motor-generators. Acting as motors, they provide thrust to launch the wing into the air. After it’s in the air, the wing turns to fly across the wind, and the resulting lifting force soon propels the wing forward without assistance. Once the forward thrust from the wind is sufficient to balance the drag from the propellers, now acting as wind-turbine blades, the motor-generators can begin generating electricity. The high velocity of the wing means that Makani’s machines don’t need gearboxes, which reduces weight and maintenance costs.

Earlier this year, Makani demonstrated automated flight control of a prototype system rated for 30 kW. The company’s engineers have asserted that its power output in different wind conditions matches their expectations, which suggests that Makani will soon have a system that can reliably produce power in the field—a first for any airborne-wind-energy company.

Engineers at Makani hope ultimately to deploy their systems offshore and feed the energy captured into the grid. I suspect that their rigid-wing flygen approach will make economic sense only for larger machines, say, those of 50-kW to 5-MW capacity. But regardless, I admire Makani’s impressive technical achievements, which are bringing airborne wind energy that much closer to commercial reality.

If getting power out of a kite still seems, well, blue-sky to you, consider that utility-scale wind turbines also seemed far-fetched 25 years ago. And the world now hasmore than 238 gigawatts of installed capacity from wind turbines, up by a factor of 10 in just one decade. It’s true that those turbines satisfy only a small portion of the world’s electricity needs. But that fraction is on the rise, and adding airborne wind energy to the mix should allow it to grow that much faster, further diminishing reliance on fossil fuels.

Success will take considerable inventiveness and a lot more experimentation by all of the groups involved. But the pioneers of aviation experienced exactly the same sorts of challenges and battled similar skepticism, and yet they overcame the obstacles. Now we reap the rewards, getting on planes without reflecting on the many individual technologies that make air travel so safe and routine. The same will happen with airborne wind energy. Future generations will benefit from it without giving much thought to all the failed experiments and countless technical wrinkles that had to be ironed out before this industry could get itself off the ground.

This article originally appeared in print as "Wind Energy Industry: Go Fly A Kite."

About the Author

Robert Creighton started developing airborne wind-energy systems while pursuing an MBA at the University of Wisconsin–Madison. There he discovered the sport of kiteboarding, which he took up so he could learn how to wrangle large kites. It paid off: The company he founded, WindLift, is among several building sophisticated kite-power prototypes.

Raising money to fund product development is never easy, as any tech entrepreneur will tell you. But I’ve had to grapple with a unique complication: My company, WindLift, is developing a kite-based system that generates electricity. The prototype, designed to put out 12 kilowatts, could save tons of money for some people now using diesel generators. But when I pitch the business to potential investors, it often seems as if all they can remember is their childhood struggles with those cheap stick-and-string fliers, making it impossible for them to envisage what my company aims to achieve.

The problem isn’t so much that most people view kites as toys—it’s that most people have no idea how sophisticated those toys have become! Take kiteboarding. Since the mid-1990s, a growing number of enthusiasts have been using large kites to enjoy an experience similar to that of waterskiing or skimming over the water on a wakeboard while being pulled by a motorboat. With kiteboarding, you dispense with the boat and are instead pulled across the waves by a good-size kite.

The kites designed for this sport measure up to 20 square meters, almost as big as a small billboard. With them, expert kiteboarders can really fly: In 2010, the world’s speed-record holder, Rob Douglas, hit 103 kilometers per hour (64 miles per hour)—faster than the fastest sailboat. And skilled kiteboarders can leap 15 or more meters into the air and then glide back gently to the water’s surface.

A kite capable of such feats isn’t anything like the ones you played with as a kid—it’s an ingeniously engineered airfoil. And by the way, it has high-tech tethers that are 15 times as strong as steel. A lot of research has gone into designing such kites and their rigging so that they can be turned on a dime with a gentle tug on the control lines. They can also be instantly adjusted to reduce the power they deliver, an important feature that allows a kiteboarder to negotiate strong, gusty winds safely.

Given these advances in kite engineering, it should come as little surprise that several companies are now trying to deploy this technology for something more than recreation. A few have attached large kites to cargo ships and motor yachts as a way to reduce their fuel consumption. My company is looking to use these airfoils to offset fuel use, too, but in a different setting—for electrical generators in remote locations where the diesel fuel to run them is a scarce commodity. Diesel in these places is so expensive that supplementing conventional generators with power produced from the wind makes good economic sense.

Mine is just one of several ongoing efforts to use kites to generate electrical power from the wind. Such airborne wind-energy systems offer many advantages over standard wind turbines, most notably that these tethered airfoils can tap the relatively strong and steady winds found higher up. In addition, the area the airfoil can sweep isn’t limited by the diameter of the turbine, so these airborne systems are inherently more efficient. Finally, the massive pylon needed to support a very large rotating blade can be eliminated, slashing construction costs and setup times.

Of course, generating electricity with a kite has some challenges you don’t have with a standard wind turbine. Turbines can’t crash, for example. To avoid such mishaps, you must be able to control the kite so that it crisscrosses the sky in an orderly fashion, despite the vagaries of the wind. You also need to automate this piloting and to make the whole system robust and reliable. So far, nothing that meets all those requirements has emerged on the commercial market, and it will probably be several years at least before anything is available that does.

I view the present situation as being akin to the pioneering days of flight, where nobody knew what configuration of wings and control surfaces would serve best—or whether the whole enterprise would prove practical at all. But if the engineers now working on this technology are persistent and clever enough, using tethered wings to generate electricity from the wind will surely progress just as quickly as early aviation did.

Photos: David Schneider (4)

FIELD TESTS: WindLift tests parts of its prototype system, including the airborne telemetry [top left], a leading-edge-inflatable kite [top right, bottom left], and a tether-wrapped drum [bottom right]. Click to enlarge.

As far back as the early 19th century,some kites were used as a power source—to propel buggies. But the first rigorous technical analysis of kites for generating electricity began in about 1980. Miles Loyd, a researcher at Lawrence Livermore National Laboratory, in California, investigated the physics of the problem, publishing his results in a journal article titled “Crosswind Kite Power” [PDF].

Loyd showed that by flying a tethered wing back and forth across the wind, you could get considerably more power than you could from a kite that just hovered in one spot. According to Loyd’s calculations, if you used a wing as big as the one on a Lockheed C-5A military transport (68 meters long), you could, at least in principle, extract a few megawatts from a 10-meter-per-second wind. That’s comparable to what you might get from the biggest of modern wind turbines.

Loyd considered two ways to get electrical energy out of a tethered wing. One is to outfit the wing itself with propeller-like turbine blades that generate power as it zooms through the air. That power would then be sent down an electrically conductive tether. This is now known as the flying-generator, or “flygen,” approach. The other technique he considered was to exploit the force that the wing exerts on its tether to generate electricity using equipment on the ground.

Loyd’s analysis didn’t examine yet another possibility: to generate electricity using turbine blades that serve as both lifting surfaces and energy-harvesting devices. That’s the technique Australian engineer Bryan Roberts began experimenting with in 1979—something he calls a gyromill, which he continues to work on with California-based Sky Windpower.

Illustration: John MacNeill

KITE-POWER MACHINE: A LOOK INTO THE INNER WORKINGS OF WINDLIFT’S PROTOTYPEThe author’s company, WindLift, built an airborne wind-energy system for engineering tests. It uses a leading-edge-inflatable kite and a ground-based generator, the main components of which are shown here. Click to enlarge.

Beginning in the 1990s, other groups around the world also began devising various ways to generate electricity with kites. But most of their plans involved ambitiously large systems that never materialized despite the many patents filed for them. Perhaps the most influential of these early innovators was Wubbo Ockels, the first Dutch astronaut, who proposed the multikite Laddermill in 1993. Although the Laddermill was never built, Ockels, now a professor of aerospace engineering, has created a well-regarded research and development program in airborne power generation at the Delft University of Technology, in the Netherlands.

Stephan Wrage, one of the founders of Hamburg-based SkySails, is another leading figure in this field, having raised more than US $70 million to develop kites for ship propulsion. The list of people and companies working on airborne wind energy goes on, with many attractive ideas still incubating [see table, “Watts Flying”].

Photos: From top: Enerkite; Kitegen research; Skysails Power

I began thinking about using kites to generate electrical power in 2005. I had just returned from a trip to Honduras, where there is a dire need for affordable power in areas not connected to the grid. Many of the people I met in the country’s rural districts relied on diesel generators, but fuel costs limited how often they could run them.

This same problem continues to hold back much of the developing world. Even mobile telephony in such places often depends on running diesel generators constantly, inflating the cost of wireless service. Indeed, the London-based GSM Association estimates that mobile-phone providers spend about $15 billion a year worldwide on diesel fuel for remote base stations.

The scarcity of diesel is also a big issue in war zones, where delivering fuel to mobile generators can cost close to $4 for each kilowatt-hour of electricity generated—tens of times the price that grid-connected consumers typically pay. So if kite power could offset even a fraction of that fuel consumption, there would be considerable savings for the military, both in money and in lives lost protecting resupply lines.

I began exploring ways to use kites to supplement diesel-powered generators while I was a first-year MBA student at the University of Wisconsin–Madison. My initial concepts ran the gamut. Totally ignorant of the earlier efforts in this sphere, I had naive ideas about what would work. Nevertheless, I founded WindLift and began looking for funding for research and development.

My first meeting with a venture capitalist brought in no money, but I got some good advice: He said I should investigate kiteboarding—a sport he had discovered while vacationing in Hawaii. After a quick Internet search, a world of expertise in harnessing the energy of big kites opened up to me. And to be sure I learned all the lessons it had to offer, I took up the sport myself.

The people constructing kites for kiteboarding have roughly the same goals as those designing kite-energy machines—to create maximum tension in the lines, which is why WindLift has been able to use off-the-shelf kiteboarding kites to test its prototype systems, the first of which I built mostly myself. In 2008, I moved my fledgling company from Wisconsin to North Carolina to take advantage of the excellent coastal winds and longer testing season there—the same reasons the Wright brothers went to North Carolina’s Kitty Hawk in 1900. Alas, the state’s coasts have been highly developed since then, and the lonely dunes over which the Wrights flew are now trampled by millions of tourists each year. So WindLift’s engineers and I conduct test flights in open fields several kilometers inland.

Our current system uses a 90-centimeter-diameter drum, which is connected to a 60-kW motor-generator built originally for a hybrid electric bus. Tension from the kite pulls the tether and turns the drum, thus generating electricity, which is stored in a bank of lead-acid batteries. Control lines attached to the wing are then adjusted to “depower” the kite, reducing the amount of lift it produces. During this phase of the cycle, electricity is fed back into the motor-generator, rotating the drum in the other direction and reeling in the kite.

We constructed our initial prototypes using ram-air wings, which are similar to those found on modern parachutes. We soon realized, though, that some internal structure was needed to stabilize flight during the retract cycle. That’s when you want the lift provided by the wing to drop to zero—or even better, to become negative, meaning that the air pushes it downward.

Ram-air wings can’t be depowered much without them completely folding up. So we switched to a leading-edge inflatable (LEI) kite, which has a long, slender air bladder at the front of the wing to help it hold its form. Even so, these wings may prove too flexible to execute a reliable retract cycle. We’re working now to find ways to reinforce them without making them so stiff that they (or the things they hit) sustain damage on hard landings. If we’re not successful, the need to be able to reel in the kite without expending much energy may ultimately force us to adopt completely rigid wings.

So far, we’ve built two ground stations and have been testing them with LEI kites normally used for kiteboarding. Those wings cannot, however, generate the huge amount of tension we configured our system for. That will soon come from new wings of our own design, which we expect to begin flying next year. In the meantime, with only standard kiteboarding kites attached, our system cannot generate much power. But our experiments with them have allowed us to compare field measurements with our numerical models and also to work on telemetry electronics and automated flight controls.

We’re not the only ones getting ready to test the winds. Among our competitors, the most advanced are using rigid wings rather than ones made of fabric. These designs tend to be more expensive, and the wings are prone to damage when they strike the ground. But those rigid airfoils are far more aerodynamic than any fabric wing, allowing them to extract more power from the wind.

Makani Power of Alameda, Calif., is one of the leading companies taking this approach. With $15 million in seed money from Google and a $3 million grant from the U.S. Advanced Research Projects Agency’s ARPA-E program, along with other private investment, Makani has built large carbon-composite wings, each outfitted with four propeller-equipped motor-generators. Acting as motors, they provide thrust to launch the wing into the air. After it’s in the air, the wing turns to fly across the wind, and the resulting lifting force soon propels the wing forward without assistance. Once the forward thrust from the wind is sufficient to balance the drag from the propellers, now acting as wind-turbine blades, the motor-generators can begin generating electricity. The high velocity of the wing means that Makani’s machines don’t need gearboxes, which reduces weight and maintenance costs.

Earlier this year, Makani demonstrated automated flight control of a prototype system rated for 30 kW. The company’s engineers have asserted that its power output in different wind conditions matches their expectations, which suggests that Makani will soon have a system that can reliably produce power in the field—a first for any airborne-wind-energy company.

Engineers at Makani hope ultimately to deploy their systems offshore and feed the energy captured into the grid. I suspect that their rigid-wing flygen approach will make economic sense only for larger machines, say, those of 50-kW to 5-MW capacity. But regardless, I admire Makani’s impressive technical achievements, which are bringing airborne wind energy that much closer to commercial reality.

If getting power out of a kite still seems, well, blue-sky to you, consider that utility-scale wind turbines also seemed far-fetched 25 years ago. And the world now hasmore than 238 gigawatts of installed capacity from wind turbines, up by a factor of 10 in just one decade. It’s true that those turbines satisfy only a small portion of the world’s electricity needs. But that fraction is on the rise, and adding airborne wind energy to the mix should allow it to grow that much faster, further diminishing reliance on fossil fuels.

Success will take considerable inventiveness and a lot more experimentation by all of the groups involved. But the pioneers of aviation experienced exactly the same sorts of challenges and battled similar skepticism, and yet they overcame the obstacles. Now we reap the rewards, getting on planes without reflecting on the many individual technologies that make air travel so safe and routine. The same will happen with airborne wind energy. Future generations will benefit from it without giving much thought to all the failed experiments and countless technical wrinkles that had to be ironed out before this industry could get itself off the ground.

This article originally appeared in print as "Wind Energy Industry: Go Fly A Kite."

About the Author

Robert Creighton started developing airborne wind-energy systems while pursuing an MBA at the University of Wisconsin–Madison. There he discovered the sport of kiteboarding, which he took up so he could learn how to wrangle large kites. It paid off: The company he founded, WindLift, is among several building sophisticated kite-power prototypes.

Δεν υπάρχουν σχόλια:

Δημοσίευση σχολίου